The Basic Principles Of Glass Infill Panels

Table of ContentsThe Single Strategy To Use For Mapes Insulated PanelsThe 25-Second Trick For Infill Panels For WindowsThe smart Trick of Glass Infill Panels For Stairs That Nobody is Talking AboutInfill Panels For Windows for Dummies

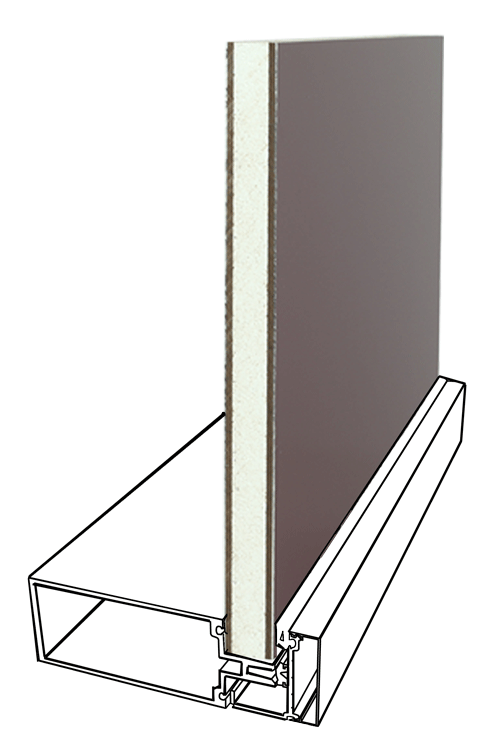

Thermal conductivity of the drape wall system is essential due to heat loss with the wall, which influences the heating & cooling prices of the building. On a badly carrying out drape wall surface, condensation may base on the inside of the mullions. This might trigger damages to surrounding interior trim as well as wall surfaces (lightweight in fill panels).Infill describes the big panels that are put right into the curtain wall in between mullions. Infills are typically glass however may be composed of nearly any exterior structure element. Some usual infills include metal panels, louvers, and photovoltaic or pv panels. Without a doubt one of the most typical glazing kind, glass can be of a nearly boundless mix of shade, density, and opacity.

1/4 inch glass is typically utilized only in spandrel locations, while protecting glass is made use of for the remainder of the structure (often spandrel glass is defined as insulating glass too). The 1 inch insulation glass is typically comprised of two 1/4-inch lites of glass with a 1/2 inch (12 mm) airspace.

Drape wall surface architecture building In household building and construction, densities generally made use of are 1/8 inch (3 mm) monolithic and also 5/8 inch (16 mm) shielding glass. Larger densities are generally utilized for structures or areas with greater thermal, relative humidity, or sound transmission demands, such as research laboratory areas or recording studios. Glass might be used which is transparent, clear, or nontransparent, or in differing levels thereof.

Not known Facts About In Fill Panels

Spandrel or vision glass may likewise have transparent glass, which could be for protection or aesthetic functions. Opaque glass is utilized in areas to conceal a column or spandrel light beam or shear wall behind the drape wall. One more technique of hiding spandrel locations is through darkness box building and construction (giving a dark enclosed room behind the transparent or translucent glass).

Fabric is one more kind of product which is usual for drape wall surfaces. Fabric is often much more economical and also functions as a much less long-term service. Unlike glass or rock, material is much faster to set up, less pricey, as well as frequently a lot easier to modify after it is set up. Due to low thickness of textiles complete weight of framework is very low after that toughness consideration of framework is not also vital.

The sort of rock utilized is restricted just by the stamina of the stone as well as the capacity to make it in the appropriate sizes and shape. Usual stone kinds used are: calcium silicate, granite, marble, travertine, and also sedimentary rock. To minimize weight and also improve strength, the all-natural stone might be affixed to an aluminum honeycomb backing.

Various other opaque panel materials index consist of fiber-reinforced plastic (FRP), stainless steel, and also terracotta. Terracotta curtain wall surface panels were first used in Europe, yet just a couple of makers generate top quality modern terracotta drape wall surface panels. A louver is provided in an area where mechanical equipment located inside the structure requires air flow or fresh air to operate.

The Ultimate Guide To Mapes Architectural Panels

Drape wall systems can be adapted to approve most sorts of louver systems to keep the same building sightlines as well as style while supplying the functionality. The majority of drape wall double glazing panel suppliers glazing is fixed, meaning there is no access to the outside of the building except through doors. However, windows or vents can be polished right into the curtain wall system too, to offer required air flow or operable home windows.

Firestopping at the, which is a space in between the flooring and the drape wall surface, is vital to reduce the flow of fire and also combustion gases in between floorings. Spandrel locations must have non-combustible insulation at the indoor face of the drape wall surface. Some building ordinance require the mullion to be covered in heat-retarding insulation near the ceiling to stop the mullions from melting as well as spreading the fire to the flooring over.

The drape wall itself, nevertheless, is not ordinarily called for to have a rating. This triggers a dilemma as Compartmentalization (fire defense) is typically based upon closed compartments to avoid fire as well as smoke migrations past internet each involved area. A drape wall surface by its actual nature avoids the conclusion of the area (or envelope).

Thus, unless the structure is sprinklered, fire may still take a trip up the curtain wall surface, if the glass on the subjected flooring is smashed from warm, triggering fires to lick up the beyond the building. Dropping glass can threaten pedestrians, firemens as well as firehoses listed below. An example of this is the 1988 First Interstate Tower fire in Los Angeles, The Golden State.

See This Report about Mesh Infill Panels

Light weight aluminum's melting temperature is 660 C, whereas structure fires can reach 1,100 C. The melting point of aluminum is normally gotten to within minutes of the begin of a fire. Fireman knock-out glazing panels are usually required for airing vent as well as emergency situation gain access to from the outside. Knock-out panels are generally fully tempered glass to allow full fracturing of the panel into small pieces and fairly safe elimination from the opening.

Boundary sealants, appropriately created and installed, have a typical life span of 10 to 15 years. Removal and substitute of boundary sealants require careful surface preparation as well as appropriate describing. Aluminum frames are normally repainted or plated. Treatment needs to be taken when cleansing locations around anodized product as some cleansing agents will certainly ruin the surface (mesh infill panels).

Recoating with an air-dry fluoropolymer finishing is possible yet calls for special surface preparation and also is not as resilient as the baked-on initial layer. Plated light weight aluminum frameworks can not be "re-anodized" in position however can be cleansed and also safeguarded by exclusive clear finishings to boost look as well as resilience. Stainless steel curtain walls require no coatings, as well as embossed, instead of abrasively finished, surface areas preserve their initial look forever without cleaning or various other upkeep.